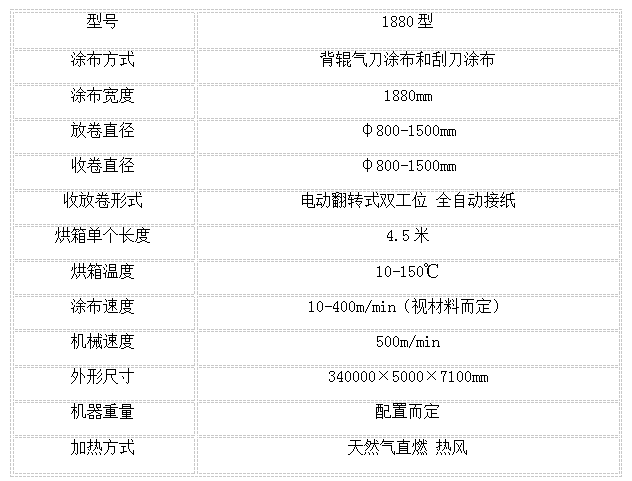

Technical parameters of 1880 thermal paper coater:

Performance and characteristics of 1880 thermal paper coater:

1. The whole machine is controlled by 5 frequency conversion motor, and the tension of the whole machine is automatically controlled by PLC frequency conversion system. The stability of the tension of the whole machine is very high through human-machine interface touch screen control and display.

2. The paper placing part is in the form of electric turnover, double station automatic paper receiving, and adopts dance roller tension control.

3. The coating method of the back roller scraper is that the material is loaded by the belt roller first, and then the back roller of the scraper is scraped quantitatively.

4. The air knife coating method of the back roll is first loaded by the belt roll, and then quantitatively coated by the air knife back roll.

5. The oven is a 4.5m oven with 6 independent frequency conversion temperature control. The heating is heated by natural gas direct combustion hot air. The hot air enters the drying system and the adjustable internal circulation suction and exhaust device. The inlet and exhaust wind force is strong, the wind force is uniform and controllable, and the drying is complete.

6. The guide wheel in the oven is actively synchronized with the host, and the transmission adopts synchronous belt wheel transmission type and net drag type to reduce material tension and deformation. The air cylinder open top oven and paper threading operation platform make it easy for operators to work.

7. The tension adopts synchronous floating swing arm type and is controlled by PLC automatic frequency conversion.

8. Automatic meter and speed control device by PLC.

9. EPC ultrasonic edge aligning machine is used for deviation correction to ensure the tidiness of material winding.

10. Key type inflatable shaft is used for retraction and release, so as to facilitate loading and unloading operation.

11. The winding part is in the form of central crimping and automatic paper receiving type.

4、 The machine is specially customized according to different requirements of customers, and the following functions can be selected:

A. The limited width range is 300-3200mm, which can be selected

B. The forms of retracting and releasing racks are: manual material lifting single station, hydraulic lifting single station, electric turnover double station, electric zipper climbing double station, electric turnover wheel disc double station, etc. for customers to choose

C. Oven heating methods are: natural gas direct combustion heating, steam heating, hot blast stove, electric heating, heat transfer oil furnace heating, etc. for customers to choose

D. The coating methods are: air knife coating, anilox roll coating, three roll coating, five roll coating, scraper coating, micro concave coating, slit coating, Mel bar transfer coating, stainless steel wire transfer coating, back roll scraper coating, etc

E. The working speed is directly proportional to the material, coating thickness, oven length and drying temperature of the coating

5、 Process flow

Automatic unwinding of substrate -- coating unit -- drying unit -- traction unit -- automatic winder

Application and application fields of 1880 thermal paper coater:

The machine is integrated by introducing foreign exquisite coater technology and many years of experience in producing coater. This machine adopts several coating functions for the production of various coating products such as special paper.